When you push down on the brake pedal, you activate a critical component of the vehicle’s braking system: the brake caliper. It performs the key function of effectively slowing down the car and stopping it. As a professional in the brake caliper industry, you definitely need to understand how brake calipers work. Our guide offers valuable insights into the braking system.

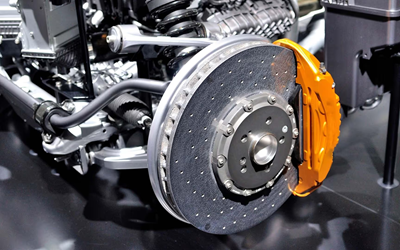

Brake calipers are responsible for pressing the brake pads against the spinning brake rotor. This pressure creates friction, which slows the vehicle down or stops it. Essentially, calipers convert the pressure from your foot on the brake pedal into the force that halts your car.

The Basic Function of Brake Calipers

Brake calipers are a key component in your car’s disc braking system. Their job is to apply pressure to the brake pads, which then clamp them onto the spinning rotor, generating friction that slows down the vehicle.

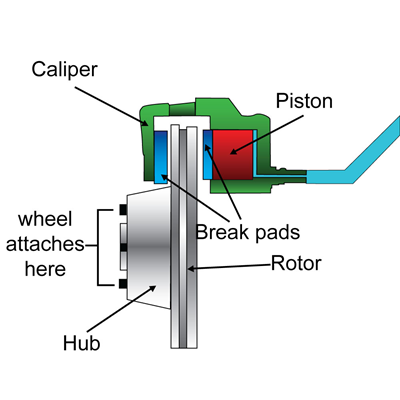

As you step on the brake pedal, the master cylinder develops hydraulic pressure. The force produced by this hydraulic pressure is transmitted through the brake lines to the calipers. Inside the calipers, this pressure forces pistons to move, pushing the brake pads toward the rotor. Then the brake pads press against the rotor to generate friction, slowing the wheel’s rotation and ultimately bringing your vehicle to a stop.

How Do Brake Calipers Work

Here’s a more detailed look at the exact steps brake calipers follow to bring your car to a halt:

Step 1: Pressing the Brake Pedal

Pressing the brake pedal initiates the braking process. When you step on the brake pedal, the pushrod linked to the master cylinder converts the pressure from your foot into hydraulic force, thereby completing the braking action. The master cylinder then pressurizes brake fluid, which travels through the brake lines to each brake caliper.

Step 2: Hydraulic Pressure Reaches the Caliper

Once the hydraulic fluid reaches the brake calipers, it activates the pistons inside them. The pressure from the brake fluid pushes the pistons outward. This movement is the key to making the brake pads contact the rotor and generate the necessary friction to slow down the vehicle.

Step 3: Movement of the Pistons in the Caliper

As the pistons are pushed outward, they apply force to the brake pads. This is what clamps the pads against the rotor. The rotor, which is connected to the wheel, is now subjected to the friction from the pads, and this frictional force gradually slows the wheel’s rotation. The stronger you step on the brake pedal, the more hydraulic pressure is generated, pressing the brake pads against the brake rotors. This intensifies the braking effect, bringing the moving vehicle to a stop.

Step 4: Friction Between the Brake Pads and Rotor

When the brake pads compress against the rotor, the friction produced by their contact slows the wheels. At this point, the kinetic energy of the moving vehicle transforms into thermal energy due to friction. The heat dissipates from the rotor, ensuring that the brakes don’t overheat immediately. The frictional force between the pads and rotor is directly proportional to the pressure applied to the brake pedal.

Step 5: Releasing the Brake

The hydraulic pressure in the brake lines decreases when you release the brake pedal. This reduction in pressure causes the caliper pistons’ seals to slightly rebound, allowing the brake pads to separate from the rotor. As the pads move away, the friction is eliminated, allowing the wheels to spin freely once again. Releasing the brakes helps reduce resistance, so you won’t feel extra drag while driving.

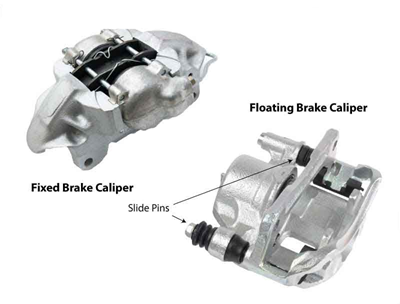

Working Operation: Floating VS Fixed Caliper

Brake calipers come in two primary types: floating and fixed. While both perform the same basic task—applying pressure to the brake pads to create friction with the rotor—their designs and working mechanisms are quite different.

Working Principle of Floating Calipers

A floating caliper has a unique design that allows it to “float” or move slightly along its bracket. This caliper typically only has one piston, which is located on one side of the rotor. When you apply pressure to the brake pedal, the piston pushes the brake pad on that side towards the rotor.

As the caliper slides along its bracket, the opposite side of the caliper also moves, which in turn pushes the brake pad on the other side of the rotor. This means that although there’s only one piston, the floating caliper uses its sliding ability to apply an even force to both brake pads. This design helps ensure that both pads press equally against the rotor, creating balanced braking pressure and reducing uneven pad wear.

Working Principle of Fixed Calipers

Unlike the floating caliper, a fixed caliper is stationary—it doesn’t move at all. The brake caliper securely mounts on the wheel and typically features multiple pistons—one on each side of the rotor. When the brake pedal is pressed down, the piston pushes both brake pads toward the brake disc together.

Because the caliper itself is fixed, the pressure from the pistons is applied evenly across both brake pads simultaneously. This provides a stronger, more consistent braking force. Fixed calipers are commonly found in high-performance vehicles and heavier vehicles, where the need for powerful and reliable braking is greater.

Conclusion

In general, brake calipers generate friction by pressing brake pads against the brake rotor to execute braking commands. From the moment you press the brake pedal to when you release it, every action is meticulously calculated to ensure driving safety. As a professional in brake components, this knowledge is essential. It is the first step in earning customer trust. Understanding your products and addressing customer inquiries will help you build partnerships and ensure your business runs smoothly.