Hello, welcome to GDST. So glad you’re here.

Who We Are

We are a factory focusing on brake cylinder manufacturing since 1995 in China. We have long been committed to providing high-quality brake cylinder products to domestic trading companies and automobile manufacturers. Under the background of global economic integration, our factory has achieved rapid development. In 2004, we established our brand – GDST, officially opening a new chapter in our foreign trade business.

With the continuous accumulation of customer resources, many overseas customers have entrusted us to find other auto parts products in China. In order to meet the diversified needs of customers, we have actively expanded new product lines and now have a full range of products covering brake parts and suspension parts.

With the growing influence of the GDST brand and the deep trust of customers, we have established close cooperative relationships with more than 300 cooperative factories. We have even reached strategic cooperation with some factories, holding their shares to seek development together and achieve win-win results. This cooperation model allows us to provide customers with a one-stop service. Whether customers need brake parts or suspension parts, we can meet most needs and ensure that customers can purchase the required parts efficiently and conveniently.

We always adhere to customer-centeredness, continuously improve product quality and service levels, and strive to create greater value for global customers. In the future, we will continue to adhere to the principle of “quality first, customer first” and work hand in hand with our partners to create a better future.

Vision

Build an Excellent one stop auto parts supply platform in the world.

Mission

Create sustainable value for our customers with first-class products and services.

Core Value

· Customers First, Win-Win Cooperation

· Ntegrity and Dedication

· Efficient Execution, Embrace Change

· Optimistic and Passionate

GDST History

1995

Establish Factory

Manufacturing high-quality brake cylinder products to domestic trading companies and automobile manufacturers.

2002

Establish GDST Brand

Relay on our advantage of brake cylinders and global economic integration, opening a new chapter in our foreign trade business.

2007

Expend Brake Parts Lines

Brake Pad, Brake Caliper, Brake Shoe, Brake Disc, Brake Drum, Brake Booster, Brake Chamber

2010

Expend Suspension Parts Lines

Shock Absorber, Control Arm, Ball Joint, Tie Rod End, Rack End, Stabilizer Link, Bushing, Strut Mount, Steering Rack, Power Steering Pump.

2022

One-Stop Service

INDUSTRY EXPERIENCE

20+ years’ export and industry experience in auto parts, served 80+ countries

LABORATORY & RESEARCH

The laboratory for analysis and quality controls our production in all stages

PRODUCT RANGE & QUALITY

All range of brake parts and suspension parts, High quality and long lasting. Cared and attractive packaging

AFFORDABLE SOLUTIONS

Manufacturer directly to grower, no middleman, help you save money

GDST Factories View

Every factory behind each of our products has undergone strict screening by GDST, ensuring long-term and stable partnerships. These collaborating factories demonstrate exceptional competitiveness in terms of both quality and pricing, providing us with absolute advantages. Therefore, you can rest assured in entrusting your orders to us. We will strictly control the quality of our products, ensuring excellence in every step of the process, while also offering you substantial profits.

Our commitment is to foster a reliable and dependable partnership with you.

GDST Globel Markets

Export to 80+ Countries, with our rich experience and cooperation, you will enjoy a smooth and worry-free experience.

Located in Wuhu City, Anhui Province, China

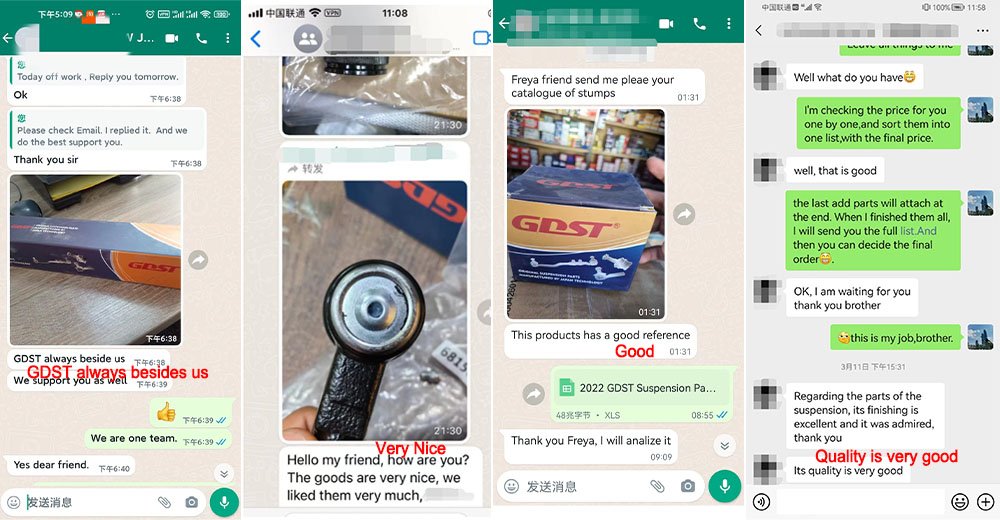

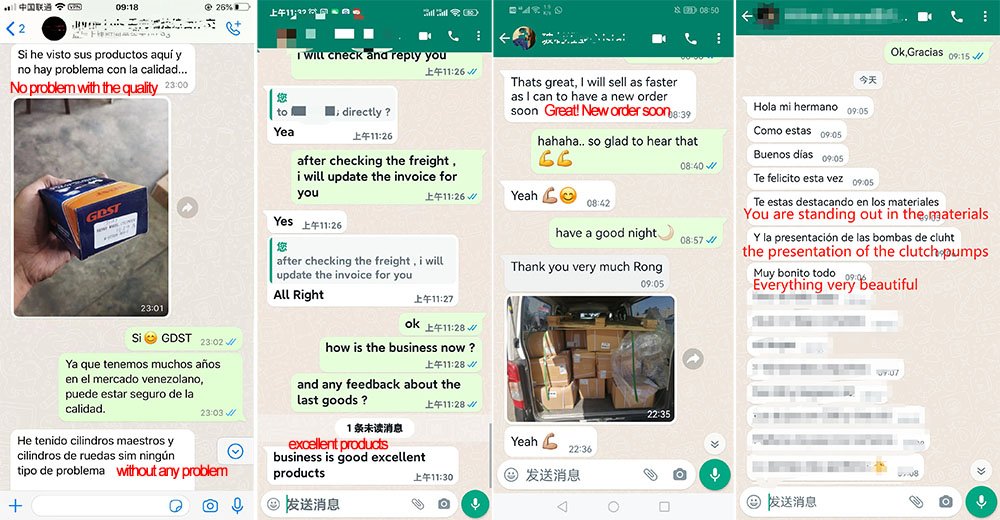

Customers Feedbacks

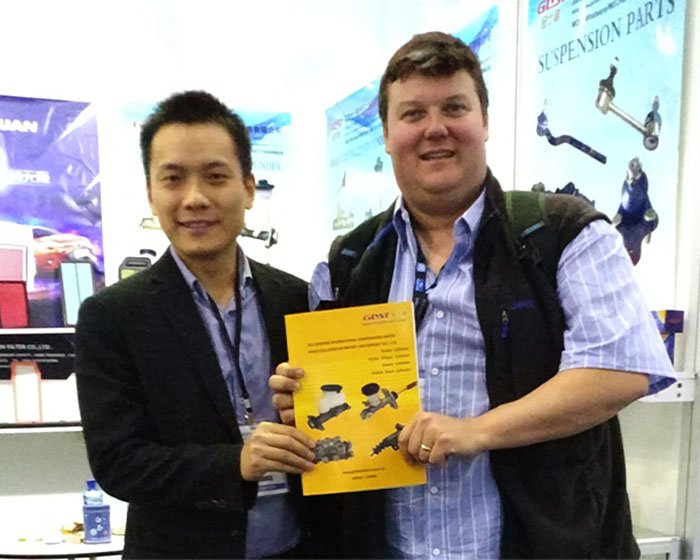

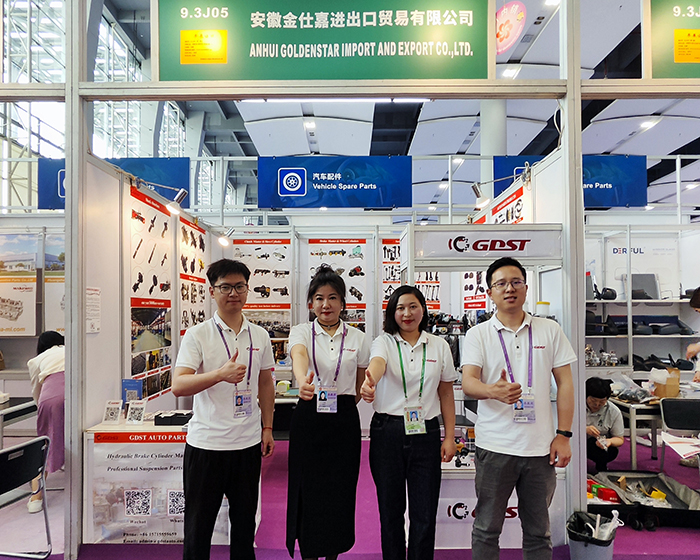

GDST Exhibitions Worldwide

Each picture represents an exhibition that GDST has participated in and records every in-depth face-to-face communication with our customers.

Interested in GDST Products? Contact Now!

Your inquiry will be send to sales manager Eric and get a reply within one working day

For us to quickly understand your request and give the exact price. Please provide your detailed inquiry list.With the following information:

1. Part number with the QTY you need

2. Any special requirements please tell us, we do our best to meet your requirement

The more information you give, the more we can easily understand your request fast and give the goods you want.

However, if you only want to know the price, send your list, and our sales will contact you to get your detailed request.