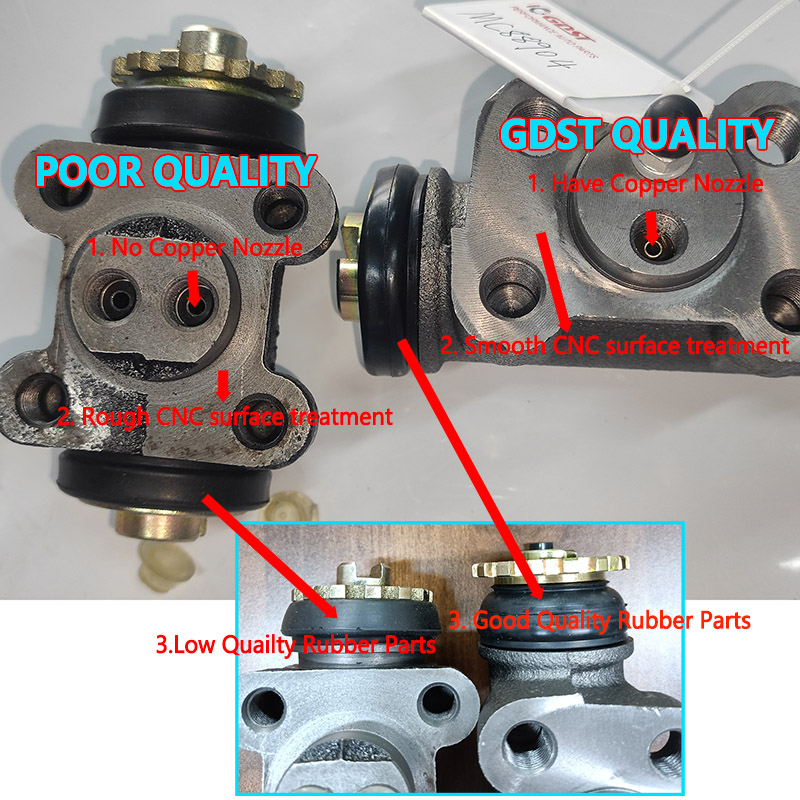

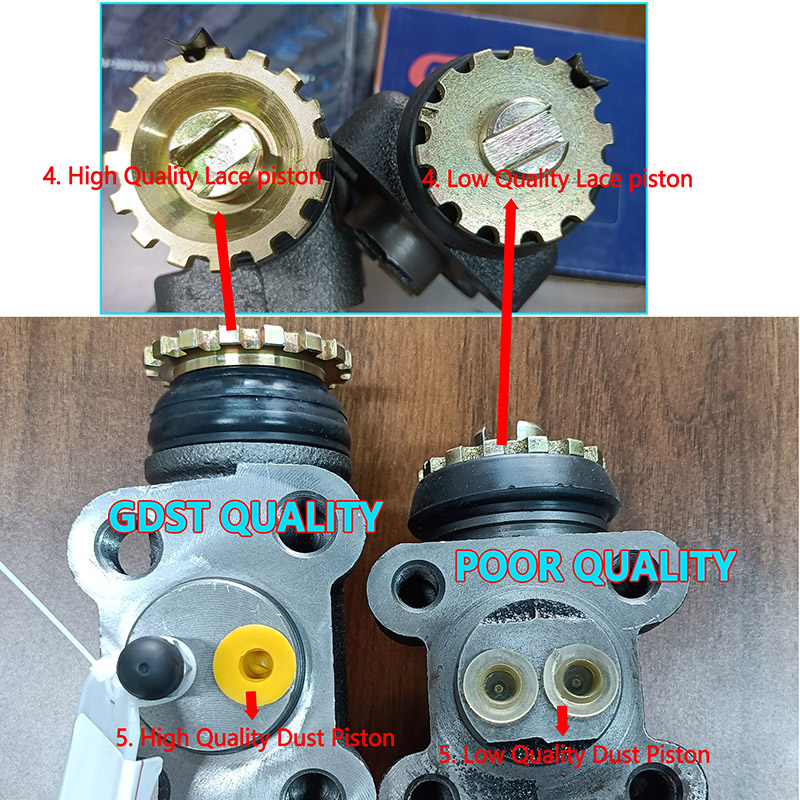

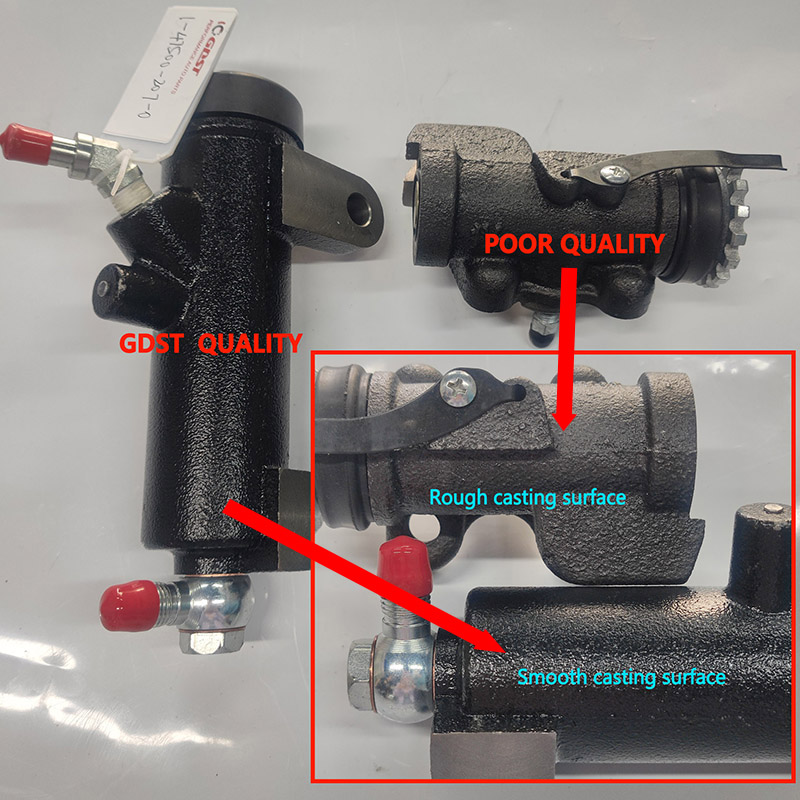

GDST Advantages

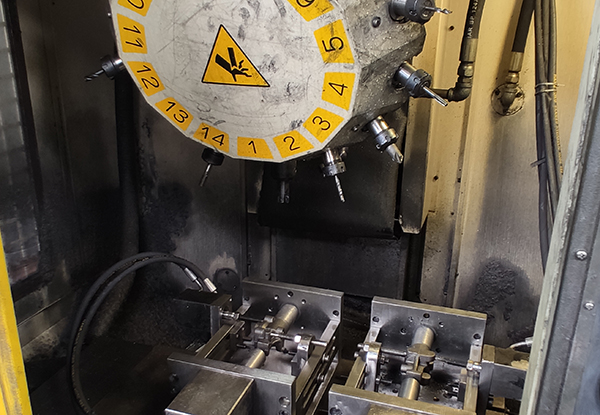

- Over 20 years of rich production experience;

- IATF16949 and SGS certification;

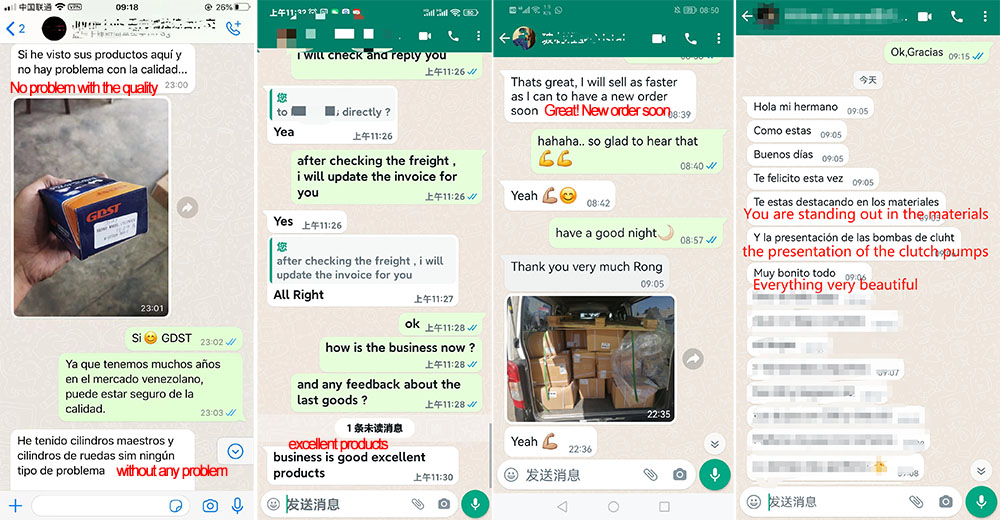

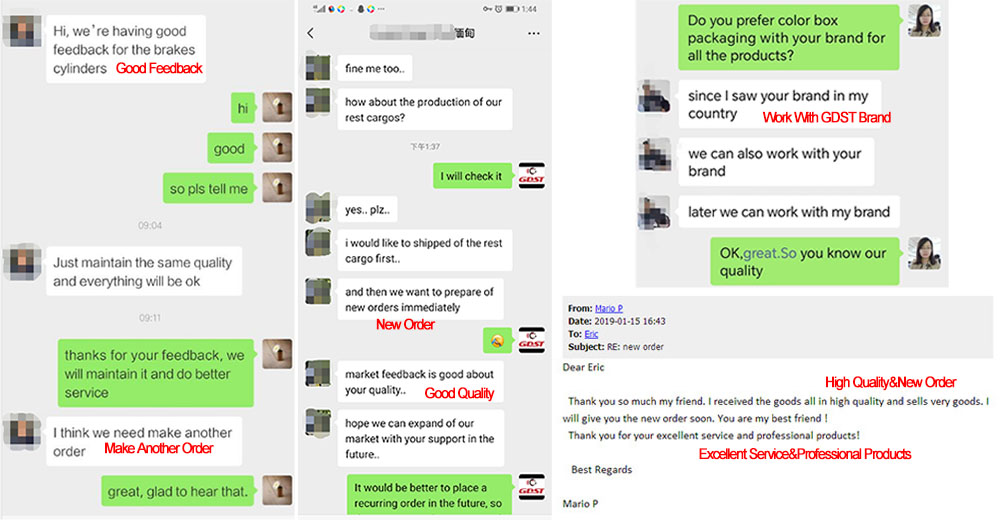

- Professional After-Sales Team;

- One year/30000km warranty;

- Lower MOQ;

- Factory direct selling prices;

- Sample available;

- OEM/ODM service,

- 45-50 days delivery time

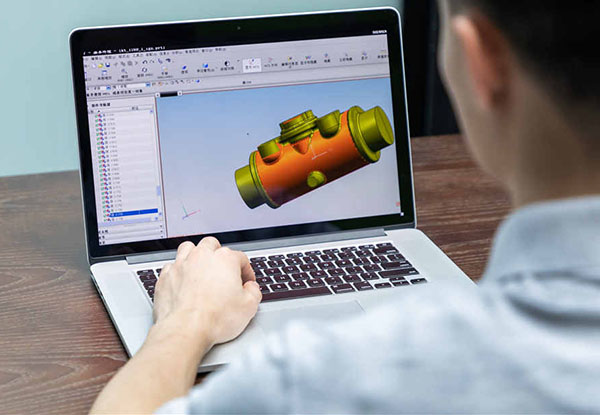

Over 20 Years Experience

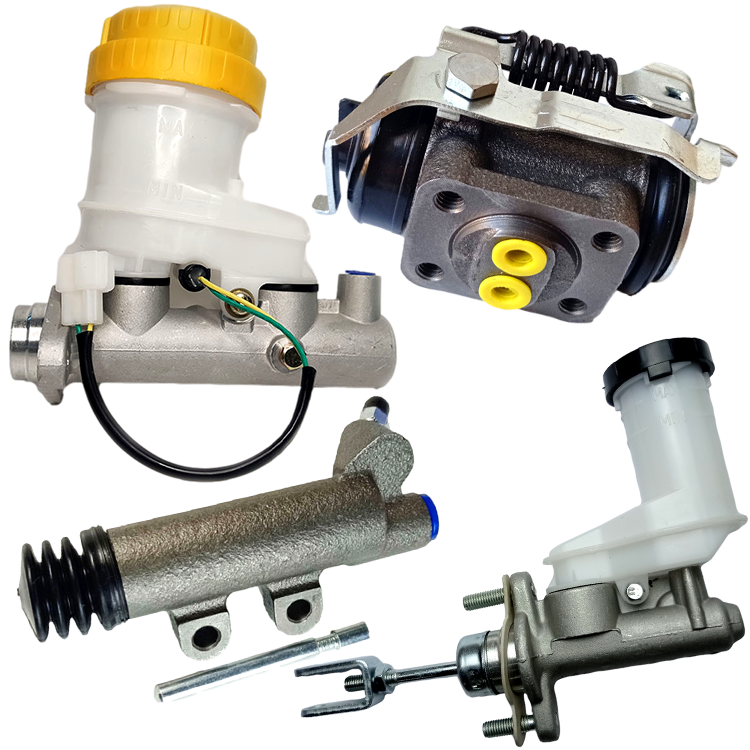

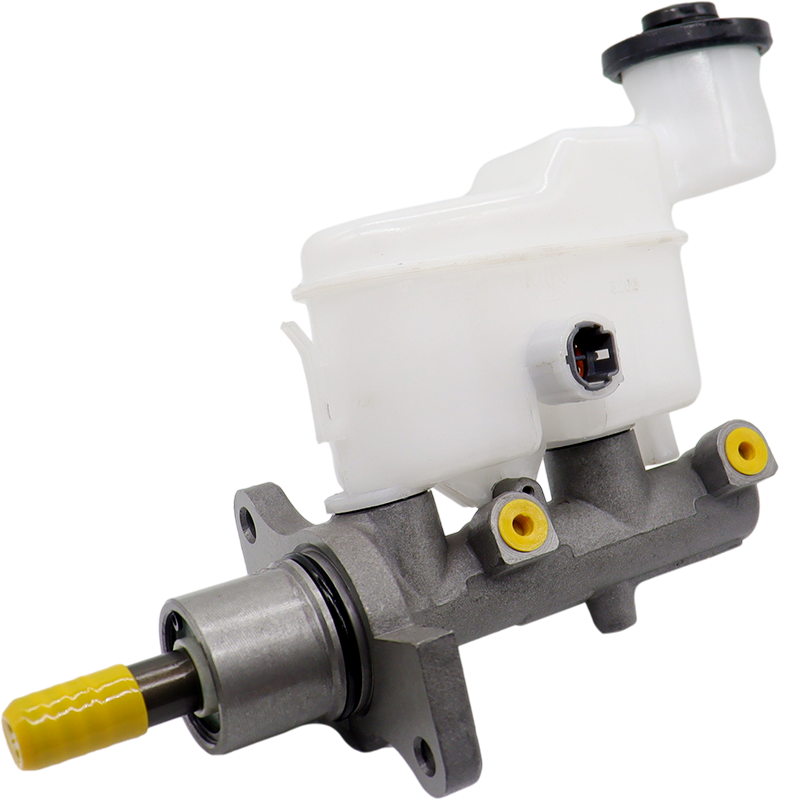

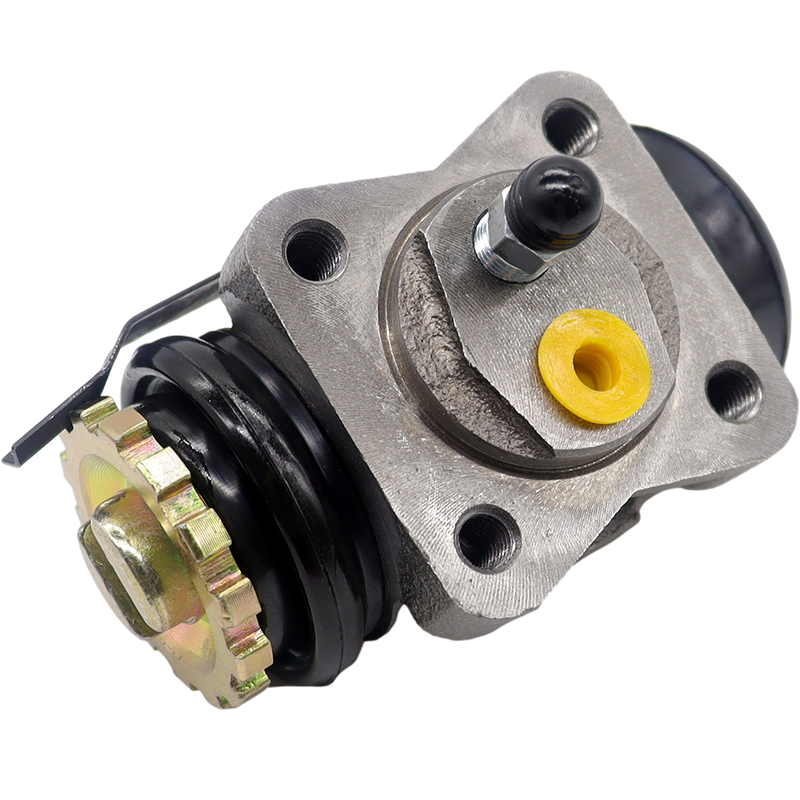

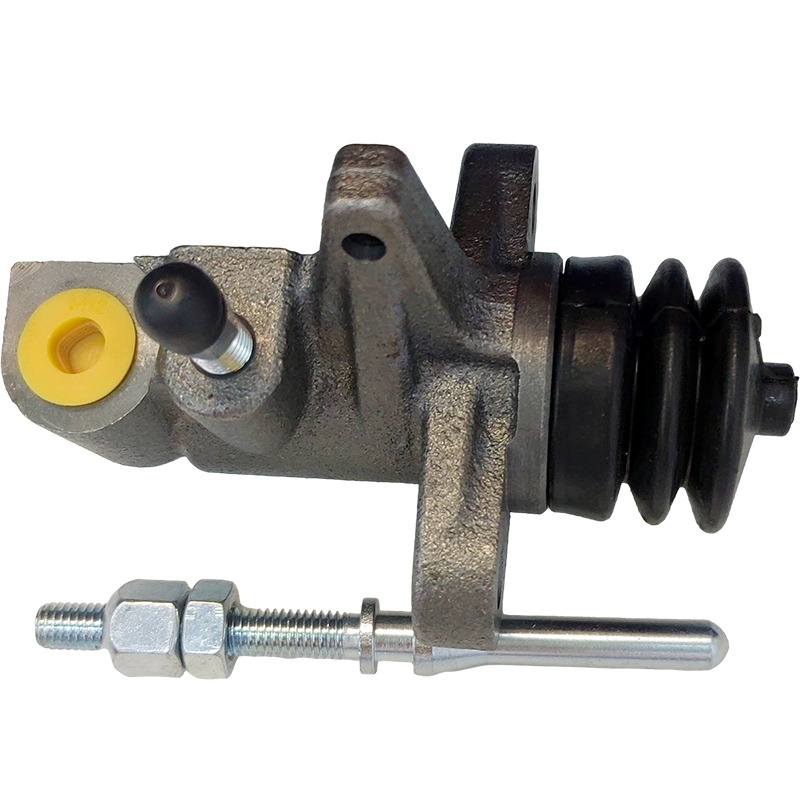

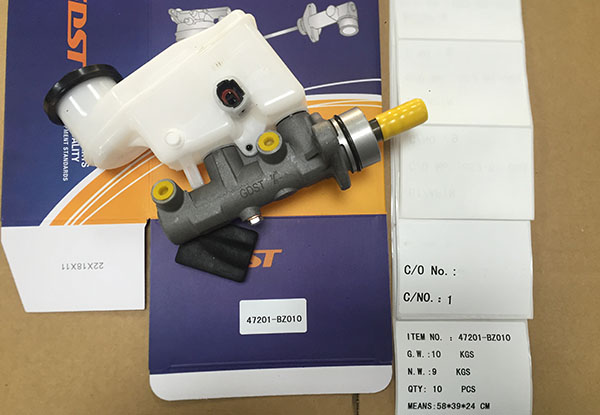

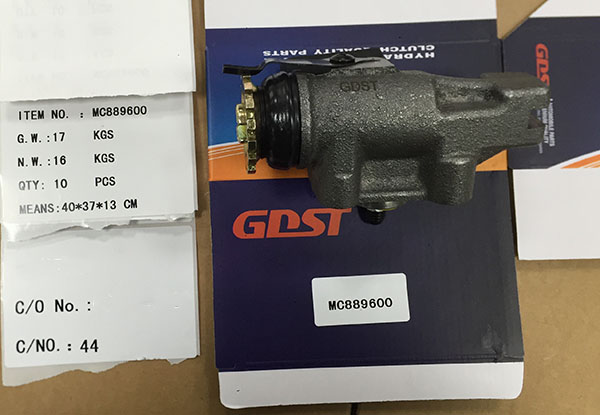

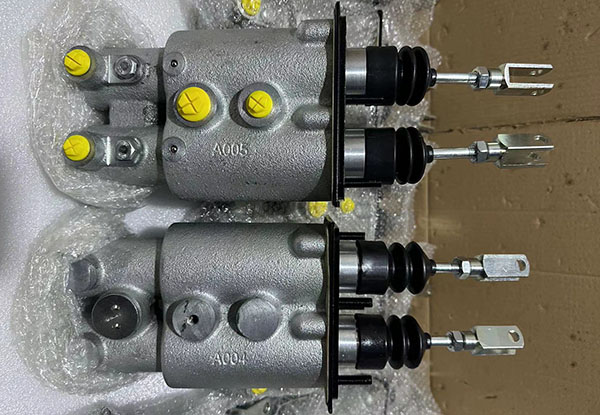

We are professional manufacturer of brake cylinders, brake pads, brake calipers, etc. Supplying high-quality products to all customers

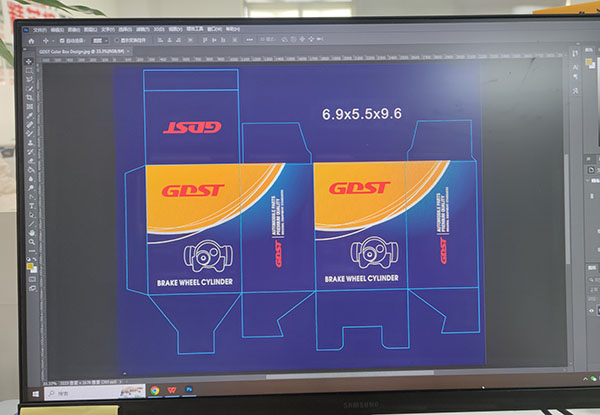

OEM and ODM Services

Support customize package design, print customized logo, customize everything exclusive to your own brand.

Assured Quality Warranty

One year/30000kms warranty

Perfect After-Sales Service

our professional sales team 24hours online to answer your after-sales problem.

Wholesale Factory Price

Factory direct selling, give all customers best prices

Certifications

IATF16949, SGS, E-mark ECE R90, AMECA