Brake Disc Manufacturer

Welcome to Brake Disc Factory! We are a professional brake disc manufacturer with competitive prices and custom services.

China Brake Disc Manufacturer

Looking for a reliable brake disc manufacturer with a wide product range? GDST is your trusted partner in the brake parts industry. With over 2,000 brake disc and rotor models, we offer complete coverage for Japanese, Korean, European, and American vehicles – including passenger cars, trucks, and commercial vehicles.

With years of manufacturing experience and strict quality control, our brake discs are built to deliver long-lasting performance, precision, and safety. Today, we export to North America, South America, Europe, the Middle East, and Africa, earning the trust of hundreds of buyers worldwide.

Whether you’re expanding your product line or looking for a reliable brake disc supplier with OEM-level quality and competitive pricing, GDST delivers. We support our partners with flexible MOQ, custom packaging, and excellent after-sales warranty.

If you’re looking for a brake disc manufacturer who delivers real value and helps your business grow, we’re ready. Let’s build a strong partnership—contact us today!

GDST Brake Discs

Brake Disc Types

The size of our brake discs is exactly according to the OE standard. Regarding the style of brake discs, we can customize them according to your needs! Welcome send your inquiry list to us now!

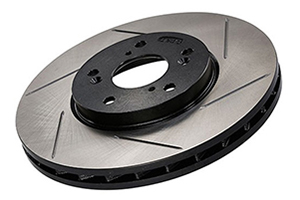

Slotted Brake Discs

- Have grooves (slots) cut into the surface.

- Improve braking performance by removing dust, gas, and water.

- Ideal for high-performance or heavy-duty use.

- Help maintain consistent braking under load.

Drilled Brake Discs

- Drill holes in the discs.

- Helps dissipate heat and reduces brake deterioration.

- Suitable for wet conditions as they allow water to escape.

- May be more prone to cracking under extreme pressure.

Slotted and Drilled Brake Discs

- Combine slots and drilled holes for dual benefits.

- Offer better cooling and dust/gas removal.

- Common in performance vehicles.

- Balanced choice between daily driving and sporty use.

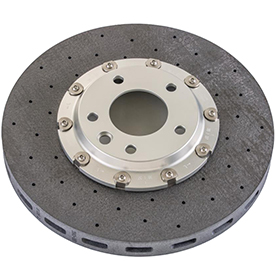

Floating Brake Discs

- Two-piece design with a floating rotor attached to a hub.

- Allows expansion under heat without warping.

- Provides better braking consistency and performance.

- Common in racing or high-performance vehicles.

Solid Brake Discs

- One-piece, flat, and simple design.

- No slots or holes; basic and cost-effective.

- Suitable for light vehicles or rear brakes.

- Less effective in heat dissipation compared to other types.

Send Inquiry Now!

Brake Disc Materials

As a brake disc manufacturer, we can customize brake discs according to your material requirements. Contact us freely!

Cast Iron Brake Disc

The most common material used in brake discs due to its excellent durability, heat resistance, and consistent braking performance. It’s a reliable and cost-effective choice, though heavier than other materials.

Steel Brake Disc

Lighter than cast iron and offer good strength and wear resistance. While they perform well under stress, they are less heat-tolerant and may warp under extreme conditions.

Carbon Ceramic Brake Disc

Known for their ultra-lightweight design and exceptional heat resistance, making them ideal for high-performance and sports cars. They offer long service life with minimal dust, but come at a high price.

Composite Brake Disc

Combine materials like carbon, aluminum, or iron to achieve a balance of lightweight construction, heat management, and strength. They are typically used in advanced or high-end vehicles for enhanced performance.

Why Work With GDST?

Lower MOQ

100set/model

Competitive Price

Factory Direct Selling

Warranty

1 Year/30000kms

Fast Delivery Time

40-45 days on time

Free Sample

Test quality before ordering

Widely Application

Looking for automotive brake discs? We’ve got you covered! GDST offers a wide variety of brake disc models that fit a full range of popular vehicles — from Nissan, Chevrolet, and Ford to Honda, Toyota, VW, Dodge, BMW, and Jeep. Whether you’re dealing in sedans, SUVs, or pickup trucks, we provide the coverage you need with quality you can trust.

OEM And ODM Service

We’re not just here to sell you brake discs — we’re here to help you grow your brand. Want your own logo on the disc? Need packaging that carries your brand’s look and feel? No problem. From custom designs to personalized packaging, we make it easy to create a product line that’s truly yours.

Reliable Quality You Can Trust

To ensure every brake disc meets the OE standards, we use professional testing methods like hardness testing, dynamic balance checks, and runout inspection. You will get brake discs with a smooth surface finish, proper thickness, and precise dimensions.

Trusted by Customers in Over 100 Countries

We’ve been in the auto parts business for years, and along the way, we’ve built lasting relationships with customers in over 100 countries. From big distributors to growing local shops, people around the world count on us for quality and support. We understand what different markets need – and we’re here to make your job easier with the right parts and the right experience behind you.

GDST Brake Disc Factory

10+ Years History

We’re a China brake disc manufacturer, and for over ten years, we’ve stayed focused on doing one thing right: making high-quality brake discs and brake rotors that our customers can truly rely on.

Whether you’re looking for PV brake discs, CV brake discs, full coated discs, Geomet coated discs, Bi-metallic brake discs, hub brake discs, slotted, drilled, or even drilled and slotted types — we’ve got them all, ready when you need them.

Our goal is simple: when customers come to us, they don’t need to look anywhere else.

Strong Production Capacity to Support Your Business

We know that a fast, reliable supply is key to helping you grow. That’s why our brake disc factory – covering 20,000 square meters and staffed by 100 skilled workers – is built for efficiency and scale. With a monthly output of 20,000 brake discs, we’re able to deliver high-quality products quickly and consistently. Whether you’re ramping up orders or entering new markets, we’ve got the capacity to keep up and the quality to back you up.

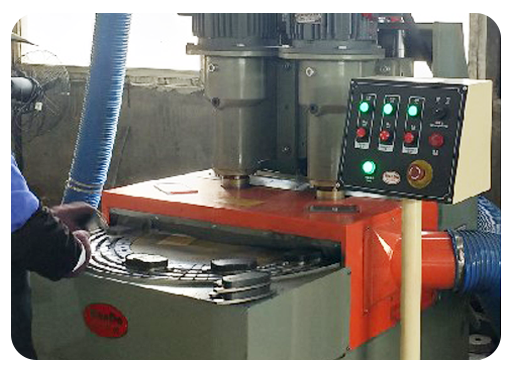

Advanced Quality Test Equipments

We take quality seriously — that’s why our brake discs go through a variety of strict tests using advanced equipment. From checking hardness and balance to measuring runout and exact dimensions with 3D tools, we pay attention to every detail. We also run salt spray tests to check coating durability, simulate real driving conditions with NVH tests, and use thermal cycling to confirm heat resistance. So when you choose us, you’re choosing tested, trusted brake discs and brake rotors you can count on – every time.

Certified Brake Disc Manufacturer

As a certified brake disc manufacturer, we proudly hold both ISO and IATF 16949 certifications, meeting strict international standards for quality management in the automotive industry. These certifications reflect our commitment to consistent manufacturing processes, product reliability, and customer satisfaction. When you work with us, you’re choosing a trusted business partner.

Production Process of Brake Discs

Step1: Material selection

The first step in the production process is selecting the appropriate material for the brake disc. Brake discs are commonly made from cast iron, which is known for its high strength and heat resistance.

Step2: Pattern making

Next, a pattern is created based on the desired shape and size of the brake disc. The pattern is typically made from wood or metal and is used to create the mold that will be used for casting.

Step3: Mold making

The pattern is used to create a mold, which is usually made from sand or other materials that can withstand high temperatures. The mold is created by packing the sand or other material around the pattern and then allowing it to harden.

Step4: Melting and pouring

Once the mold is ready, the chosen material for the brake disc, such as cast iron, is melted in a furnace to a liquid state. The molten metal is then poured into the mold, filling the cavity and taking on the shape of the brake disc.

Step5: Cooling and solidification

After the molten metal is poured into the mold, it begins to cool and solidify, taking on the shape of the brake disc. The cooling process is carefully controlled to ensure that the brake disc solidifies evenly and with the desired properties.

Step6: Shakeout and cleaning

Once the brake disc has solidified and cooled, the mold is removed, and the brake disc is shaken out of the mold. Any excess sand or other debris is removed from the brake disc, and it is cleaned to prepare it for further processing.

Step7: Machining and finishing

The rough casting of the brake disc is usually machined to achieve the desired dimensions, smoothness, and surface finish. This may involve processes such as milling, grinding, drilling, and balancing to ensure the brake disc meets the required specifications.

Step8: Surface coating (Anti-rust)

Depending on the brake disc’s requirements and intended use, a surface coating may be applied to improve its performance. For example, Geomet handling, Electrofusion treatment.

Step9: Quality control

Throughout the production process, quality control measures are taken to ensure that the brake discs meet the required specifications and performance standards. This may involve inspections, measurements, and testing to check for defects, dimensional accuracy, and performance characteristics.

Step10: Packaging

Once the brake discs have passed the quality control checks and are deemed acceptable, they are packaged and prepared for shipment to their intended destinations.

Customers Feeback

Our brake pads are sold to over 100 countries, including North and South America, Europe, the Middle East, Southeast Asia, and Africa, where we have received great feedback for our quality.

FAQ About GDST

Are you a trading company or factory?

We are both a brake disc manufacturer and trading company, we started as a brake disc factory, and after decades of working with our customers, we also help our customers to purchase other brake parts, which has allowed us to expand and develop the advantage of being able to provide one-stop service to our customers. Welcome you to inquire!

What’s your MOQ?

Normally MOQ is 100pcs per model. For the new clients, MOQ 50pcs/model also is supported. We are willing to let customers experience our products to know our products quality first.

Can I Do My Brand Package?

As a brake disc manufacturer, we offer customized brand packaging services to bulk brake disc buyers. Additionally, we provide printing services for your company logo, product model, or any other information you want to display on brake disc.

What’s your quality guarantee?

Our brake discs warranty assure 12 months after you receive our packages and every client will get our lifelong after-sale service.

What is your delivery time?

Normally, delivery time is around 45 days after the order confirmed.

Urgent orders, we can handle special.

Could I get a sample?

Welcome to try our products. Just pay the freight. The freight will return back once you place an order.

Let GDST Boost Your Business Today!

To help us respond quickly to your request for brake disc prices, please feel free to leave a message with your inquiry list, including the quantity you need. Our professional GDST team will get back to you within 6 hours with a detailed quotation and any additional information you may need.