When you’re in the automotive industry, choosing the right brake discs is crucial. But if you’re like many businesses, you might be wondering: what are brake discs made of?

It’s a vital question since the material affects not only the performance of the vehicle but also the durability and cost of production.

In this article, we will explain more details about the common materials used for brake discs—cast iron, carbon, and more—so you can make the best choice for your business.

What Materials Are Brake Discs Made Of?

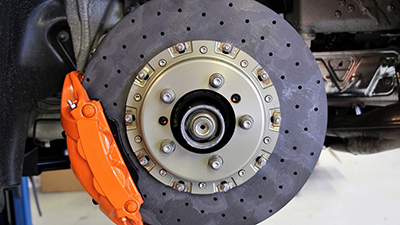

Brake discs are important components of a vehicle’s braking system. They are made of different materials, but the two most common are cast iron and carbon.

Each material offers its own set of advantages and disadvantages, depending on the vehicle’s use case and performance requirements.

- Cast Iron: The most widely used material. Because it is durable, has great heat resistance, and is relatively inexpensive to manufacture. Cast iron is perfect for everyday vehicles where the emphasis is on longevity and cost-effectiveness.

- Carbon: While more expensive than cast iron, carbon brake discs offer superior thermal resistance and are much lighter. These qualities make carbon ideal for high-performance vehicles like sports cars and race cars, where weight reduction and heat dissipation are crucial.

Other materials such as carbon-ceramic composites are also used in specialized vehicles, but cast iron and carbon are the most prevalent in the automotive industry.

What Is the Best Material for Brake Discs?

The best material for brake discs depends on the hottest demand in your existing market as well as the models your business covers, let’s break it down:

- For everyday vehicles: Cast iron is often the best choice. It’s durable, affordable, and performs well for standard braking needs. Cast iron is also easy to machine and relatively easy to source, making it the go-to material for most manufacturers.

- For performance vehicles: If your business deals with high-end, performance, or racing cars, carbon brake discs might be the way to go. While they are significantly more expensive than cast iron, their weight-saving benefits and high thermal resistance make them ideal for applications where performance and heat management are key.

- Long-term cost-effectiveness: If you’re more concerned about price, cast iron is the most affordable option without compromising performance.

In short, there’s no one-size-fits-all answer, but understanding the materials can help you make the best decision for your business.

What Are the Benefits of Cast Iron Brake Discs?

Cast iron brake discs have been the industry standard for many years, and for good reason.

Despite the rise of high-performance materials like carbon, cast iron remains the most popular choice for many vehicle manufacturers.

Here are the key benefits of cast iron brake discs:

- Cost-Effective: Cast iron is significantly more affordable than alternatives like carbon or carbon-ceramic. This makes it an ideal choice for mass-market vehicles, commercial fleets, and budget-conscious consumers.

- Excellent Heat Dissipation: maintaining consistent braking performance and preventing overheating, which could lead to brake fade. This makes cast iron brake discs reliable for everyday driving.

- Durability: Cast iron has excellent strength and durability and can withstand the wear and tear of daily use and maintain good performance for a long time.

- Widely Available: Cast iron is a common material, a convenient and reliable option for both manufacturers and businesses that need consistent supply and cost-effective pricing.

What Are the Benefits of Carbon Brake Discs?

Carbon brake discs offer several key benefits, especially for high-performance vehicles. Here’s why carbon is preferred in racing and sports cars:

- Lightweight: Carbon is much lighter than cast iron, which helps reduce the vehicle weight. This, in turn, improves fuel efficiency and vehicle handling.

- High Thermal Resistance: Carbon discs can handle much higher temperatures without compromising performance, making them perfect for vehicles that experience extreme braking conditions, such as racing cars.

- Faster Cooling: Carbon discs cool down quicker than cast iron, which is critical in high-performance situations where repeated braking can generate a lot of heat.

- Increased Longevity: While carbon is more expensive, it tends to last longer than cast iron, especially in high-performance settings, due to its better heat management and lower wear rates.