China Brake Cylinder Manufacturer

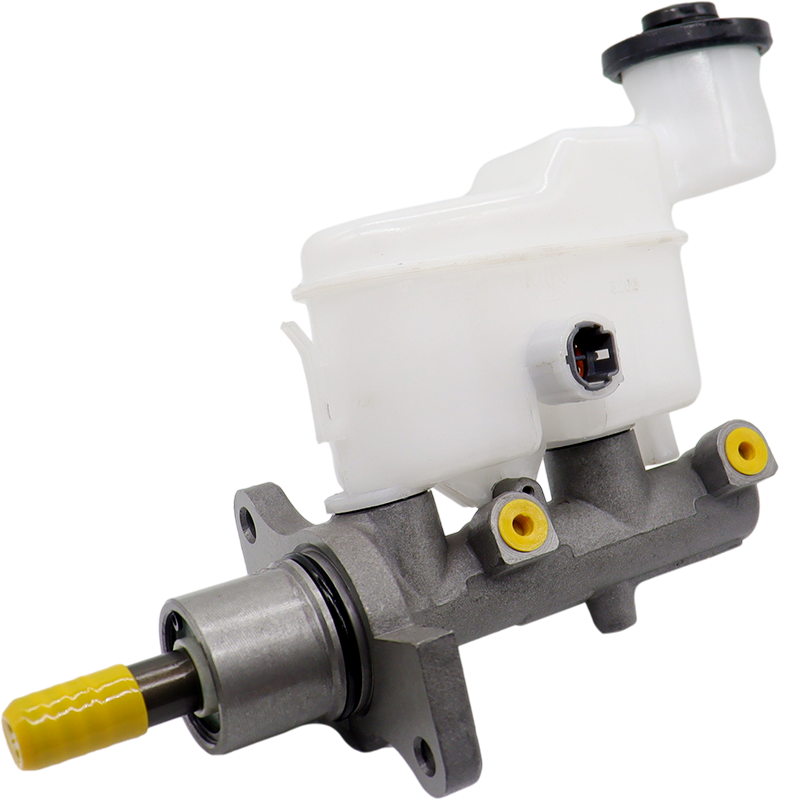

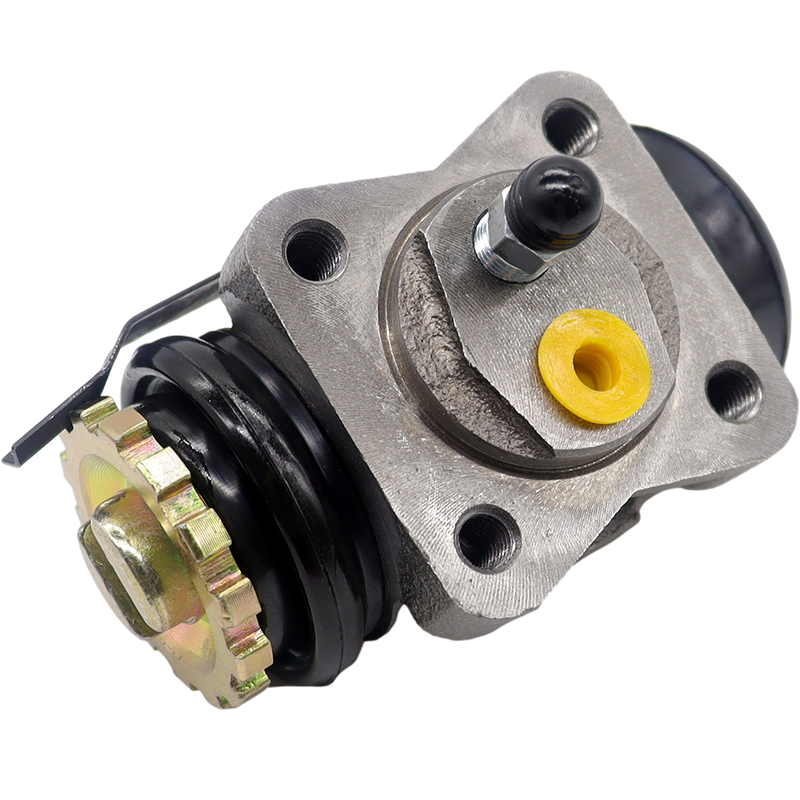

Looking for a reliable brake cylinder manufacturer to support your business? GDST specializes in manufacturing brake master cylinders and brake wheel cylinders with strict OE standards for the global aftermarket.

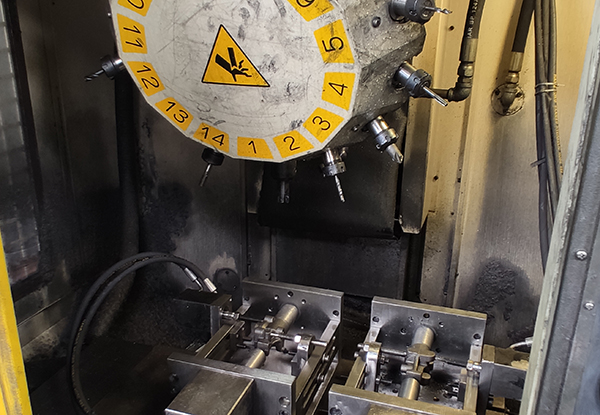

Our factory has successfully passed TRW’s factory audit, with all production and testing equipment upgraded according to their requirements. This ensures each brake cylinder we produce meets 100% OE specifications, delivering stable quality and performance you can trust.

With 8,000+ brake cylinder part numbers in our catalog, GDST covers Japanese, Korean, European, American, and Chinese vehicle applications, meeting 98% of market demand.

Whether you are expanding your product line or looking for a reliable brake cylinder supplier, GDST is here to support your business.

GDST Brand Box

We understand that packaging can make a difference in how your products are received by the market. That’s why we offer three packaging choices for our clutch slave cylinders: our GDST brand, known for its professional image and quality reputation; our GBrake brand, which many of our clients use for mid- to high-end markets; and a neutral color box, ideal for those who prefer unbranded packaging or want to add their own labels. This flexibility gives you the freedom to position the product according to your market strategy — whether you’re pushing a brand or keeping things simple.

Why Work With GDST?

Lower MOQ

100pcs/model

Competitive Price

Factory Direct Selling

Warranty

1 Year/30000kms

Fast Delivery Time

40-45 days on time

Free Sample

Test quality before ordering

Cover Full Range Models You Need

We offer over 8,000 brake cylinder models, covering a wide range of popular vehicle applications in the market, including Mitsubishi, Isuzu, Honda, Hino, Suzuki, Toyota, Nissan, DAF, Iveco, Volvo, Renault, Hyundai, etc.

OEM & ODM Service for Your Brand

We support custom branding, including printing your logo on the products and creating color bags and boxes with your brand design. For models that are not yet developed, we also offer customization based on your samples.

Outstanding Quality

We use copper nozzles for better durability.

The surface of each brake cylinder is CNC-machined for a smoother, more refined finish.

We also use high-quality brake cylinder components – such as seals, O-rings, and pistons – to ensure longer service life and more stable performance.

Rich Market Experience

We’ve worked with customers in over 100 countries, so we know what different markets need. Whether you’re in South America, North America, Europe, Africa, the Middle East, or Southeast Asia, our experienced sales team can give you professional advice and market recommendations to boost your business.

GDST Brake Cylinder Factory

30 Years History

Our brake cylinder factory was established in 1995 and is located in Wuhu City, Anhui Province—one of China’s major automotive parts industrial hubs. Over the past 30 years, thanks to the continued support of our long-term customers, we have consistently developed new brake cylinder models to expand our product range and better meet the demands of the global market. Today, we have grown into a strong and reliable manufacturer with three production facilities, ready to support large-scale orders and long-term partnerships worldwide.

Factory Scale

As a professional brake cylinder manufacturer, our factory spans an area of 10,600 square meters and employs 150 skilled workers, including a casting workshop, a CNC machining workshop, an anodizing workshop, an assembly workshop, a quality testing workshop, a packaging workshop, and a warehouse to ensure the highest quality at every stage of production.

Production Capacity

With our current production equipment and workforce, we are capable of an annual output of approximately 2 million pieces. Our large production capacity allows us to quickly arrange customer orders and ensure timely delivery, meeting the demands of both distributors’ and wholesalers’ orders.

Export Value

We export around 15 million USD worth of brake cylinders every year. This includes brake cylinders under our GDST brand and customers’ brands. Our export volume reflects the trust and satisfaction our clients have in our brake cylinders, as we strive to meet their needs with high-quality products.

Certified Brake Cylinder Manufacturer

As an ISO and IATF 16949 certified brake cylinder factory, GDST strictly follows international standards for automotive quality management. Choosing GDST to reduce risks for your business and building a strong reputation in your market.

GDST Brake Cylinders

-

GDST Rear Left Brake Wheel Cylinder W023-26-710 W023-26-710A for Isuzu

-

GDST Rear Right Brake Wheel Cylinder W023-26-610 for Isuzu W023-26-610A

-

GDST Rear Left Brake Wheel Cylinder W023-26-510 W023-26-510A for Isuzu

-

GDST Rear Right Iron Brake Wheel Cylinder W023-26-410 W023-26-410A for Isuzu

-

GDST Automotive Parts MB894211 Auto Brake Systems Auto Parts Brake Master Cylinder For Mitsubish

-

GDST Automotive Professional Accessory Brake Pump MB295340 Brake Master Cylinder For Mitsubish

-

GDST Good Quality Brake Parts Brake Pump OEM MB162441 Brake Master Cylinder For Mitsubish

-

GDST 47200-1210 472001210 Brake Master Cylinder Assembly For HINO

-

GDST Auto Brake Parts Brake Bump 46010-T8601 46010T8601 Brake Master Cylinder For Nissan

-

GDST Automotive 41100-0T00 41101-0T00 41102-0T00 41103-0T00 Brake Master Cylinder For Nissan

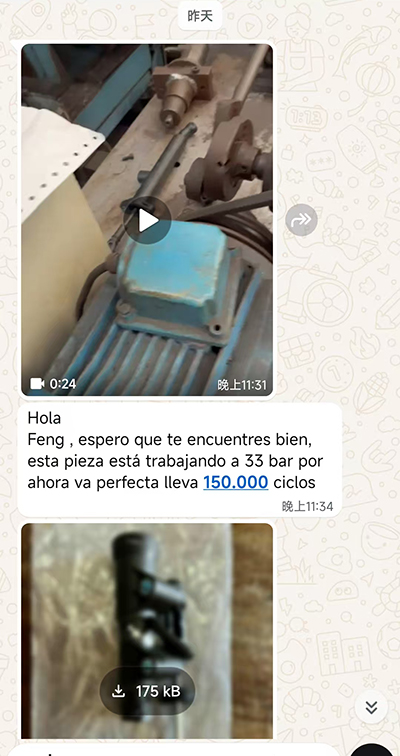

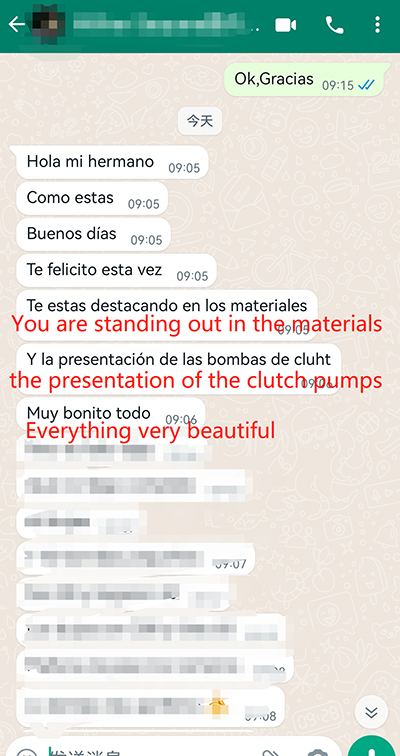

Customers Feeback

Our brake cylinders are sold to over 80 countries, including North and South America, Europe, the Middle East, Southeast Asia, and Africa, where we have received great feedback for our quality.

Let GDST Boost Your Business Today!

At GDST, we take pride in producing top-quality brake cylinders at competitive prices. Our motto is simple: ‘Quality First, Customer First.’ If you’re in search of a trusted brake cylinder manufacturer, we’d love to hear from you and provide more details on how GDST team can support your needs.