Brake Shoe Manufacturer

Welcome to Brake Shoe Factory! We are a professional brake shoe manufacturer with competitive prices and custom services.

Brake Shoe Manufacturer in China

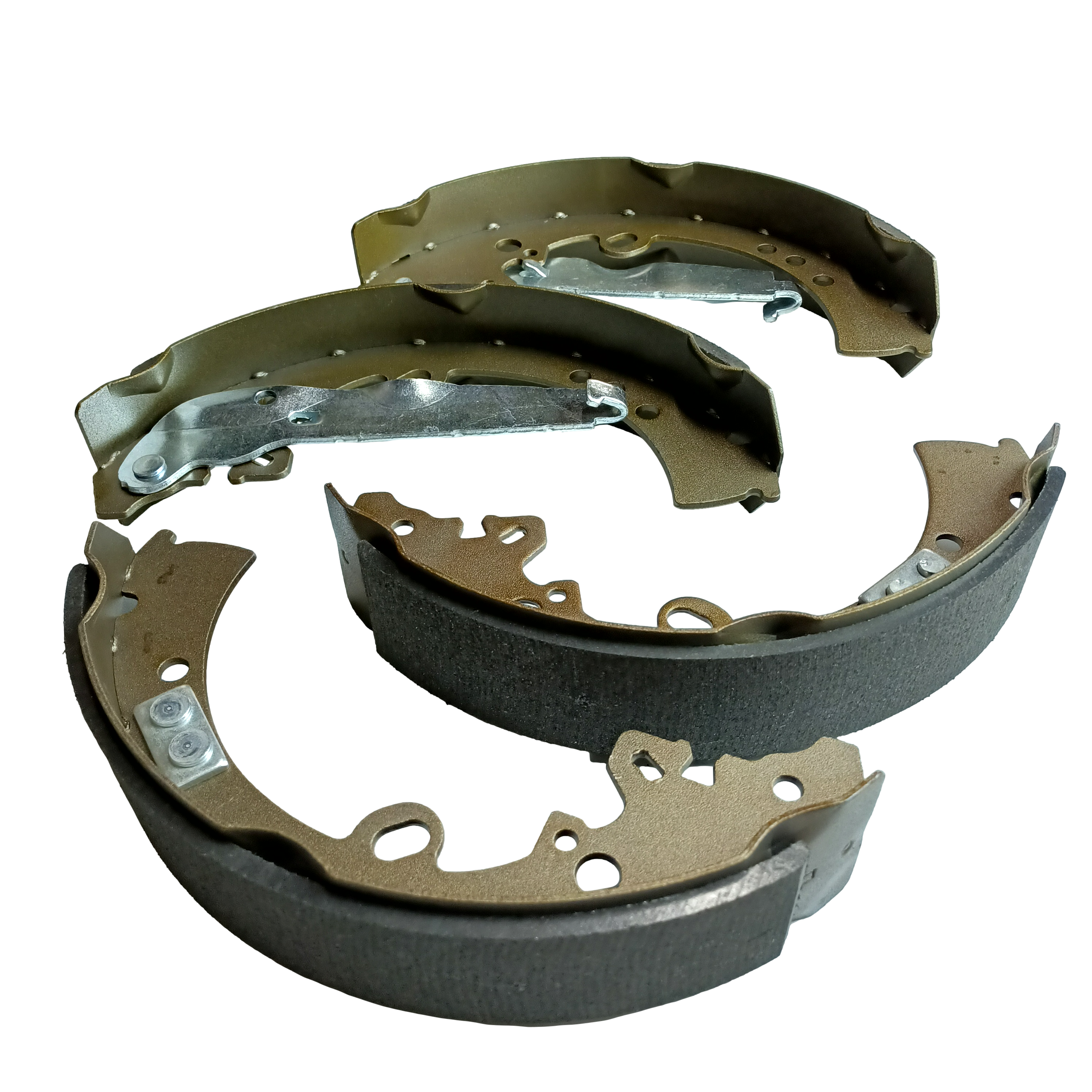

GDST is a leading brake shoe manufacturer in China, producing high-quality automotive brake shoes for the global aftermarket. Our drum brake shoes cover a wide range of Japanese, Korean, European, and American vehicles, including trailers, tractors, cars, trucks, and racing.

We use premium friction materials and strict quality control to ensure that every brake shoe delivers consistent braking performance, durability, and heat resistance. Whether you need trailer brake shoes, truck brake shoes, or car brake shoes, GDST offers reliable brake shoe replacement solutions that meet OE standards and exceed customer expectations.

Looking for a trusted supplier of tractor-trailer brake shoes or automotive brake shoes? Contact GDST today and let our experienced team support your business with quality products and professional service.

GDST Brake Shoes

FAQ About Brake Shoes

What do brake shoes do?

Brake shoes help your vehicle slow down or stop. When you press the brake pedal, the brake shoes touch the inside of the brake drum, creating friction that makes the wheels slow down, especially in drum brake systems, which are often found on the rear wheels of many vehicles.

You can see them in: Small cars and sedans (especially older models), trucks and trailers (because drum brakes are durable and handle heavy loads well), tractors and other heavy-duty or off-road vehicles, and some racing or performance vehicles.

What is the difference between brake pads and shoes?

Brake pads and brake shoes both help your vehicle stop, but they work in different types of brake systems.

- Brake pads are used in disc brakes. When you step on the brake pedal, the brake pads clamp onto a spinning brake rotor (called a brake disc) to create friction and slow your car down.

- Brake shoes are used in drum brakes. It pushes outward against the inside of a brake drum to create friction and stop your car.

In short:

- Brake pads go on the outside (disc system),

- Brake shoes press from the inside (drum system).

Both do the same job – just in different ways.

How do you know if brake shoes are bad?

You might have bad brake shoes if you notice any of these signs:

- Noisy Brakes: If you hear grinding, squealing, or scraping sounds when you brake, it often means the brake shoes have worn down and the metal parts are rubbing against the brake drum.

- Reduced Braking Power: When your brake shoes are thin or damaged, it takes more effort and distance to slow down or stop your vehicle. You might notice the brakes feel “soft” or less responsive.

- Brake Pedal Issues: A brake pedal that feels spongy, sinks toward the floor, or requires you to press harder than usual can be a sign that the brake shoes need attention.

- Vibrations or Pulsing: If you feel shaking or pulsing through the brake pedal when stopping, uneven wear on the brake shoes or brake drums could be the cause.

- Visual Inspection: If you or a mechanic remove the wheel and brake drum, worn brake shoes will look thin (usually less than a few millimeters of friction material left) or cracked.

- Brake Warning Lights: Some vehicles have sensors that trigger a dashboard light when brake components, including shoes, are worn out.

- Pulling to One Side: If your vehicle pulls sideways when braking, it may be due to uneven or damaged brake shoe wear.

If you notice any of these signs, it’s best to get your brakes inspected right away. Driving with worn brake shoes is risky and can damage other brake parts.

What happens if you don't replace brake shoes?

If you don’t replace worn-out brake shoes, several problems can happen:

- Reduced braking power: Your car won’t stop as quickly or smoothly, which increases the risk of accidents.

- Damage to other parts: Worn shoes can cause damage to the brake drum and other brake components, leading to more expensive repairs.

- Noisy brakes: You’ll likely hear grinding or scraping sounds as metal rubs against metal.

- Brake failure: In the worst case, your brakes might fail, making it dangerous or impossible to stop your vehicle safely.

- Increased repair costs: Ignoring worn brake shoes can lead to bigger, costlier damage down the road.

Replacing brake shoes on time keeps your braking system working well and your vehicle safe.

Why do brake shoes last longer than brake pads?

Brake shoes usually last longer than brake pads because of how and where they work. Brake shoes are used in the rear wheels, where braking isn’t as strong, so they don’t wear out as fast.

Also, drum brakes (which use brake shoes) spread out the heat and pressure better than disc brakes, so the shoes wear down more slowly.

In short, brake shoes don’t do as much work as brake pads, so they last longer.

Brake Shoe Materials

As a brake shoe manufacturer, we can customize brake shoes according to your material requirements. Contact us freely!

Ceramic Brake Shoes

Made of ceramic materials, such as ceramic fibers and non-ferrous metal powders, combined with fillers and binders. Ceramic brake shoes provide excellent braking performance, including high heat resistance, low noise, low dust, and long lifespan. They are commonly used in high-performance vehicles and luxury cars, but they tend to be more expensive than organic or semi-metallic brake shoes.

Low-Metallic Brake Shoes

Formulated with low-metallic friction materials, which are known for their high friction coefficient and excellent heat dissipation properties. They are ideal for heavy-duty applications that require increased stopping power and improved heat management.

Semi-Metallic Brake Shoes

Made of a combination of organic materials and metal fibers or particles, such as steel or brass. Semi-metallic brake shoes offer better performance in terms of heat dissipation and durability compared to organic brake shoes, making them suitable for heavier vehicles or high-performance applications. However, they may produce more noise and dust, and can wear down the brake drum faster.

Organic Brake Shoes

Made from materials like rubber, resin, and fibers. They’re affordable, quiet, and produce less dust, making them a good choice for everyday driving. However, they wear out faster and don’t handle high heat as well, so they’re not ideal for heavy-duty use.

Why Work With GDST?

Lower MOQ

100sets/model

Competitive Price

Factory Direct Selling

Warranty

1 Year/30000kms

Fast Delivery Time

40-45 days on time

Free Sample

Test quality before ordering

Widely Application

Need brake shoes for Ford, Toyota, Chevy, Honda, Dodge, Jeep, Nissan, GMC, VW, Silverado, Hyundai, Suzuki, Volvo, Isuzu, Hino, or other brands? GDST has you covered. We supply a wide range of drum brake shoes for Japanese, Korean, European, and American vehicles, making us your trusted one-stop supplier for quality and compatibility.

OEM & ODM Service for Your Brand

To help you stand out in a competitive market, we offer full packaging customization for brake shoes—whether it’s printing your logo on the product or designing color boxes, everything is tailored to boost your brand image and support your sales.

For brake shoe models that haven’t been developed yet, we also offer custom production based on your samples, ensuring you get the exact fit and performance your market requires.

Trusted by Customers in Over 100 Countries

With customers in over 100 countries, GDST has deep insight into the needs of different markets. As an experienced and globally recognized brake shoe manufacturer, we’re here to offer expert guidance, fast and reliable shipping, and high-quality products that meet OE standards—all to make your sourcing process easier and more efficient.

Certified Brake Shoe Manufacturer You Can Trust

Certified with ISO and IATF 16949 standards, GDST is committed to delivering high-quality manufacturing at every step. By choosing our reliable brake shoes, you can build customer trust, reduce after-sales problems, and grow your business with confidence.

GDST Brake Shoe Factory

20+ Years History

Since 2000, our factory has been dedicated to the development and production of automotive brake shoes. Backed by strong technical expertise, a skilled R&D team, and continuously growing production capacity, we’ve established a solid quality management system to ensure every product delivers reliable performance and durability.

We’re committed to building lasting partnerships based on trust and mutual growth. That’s why customers continue to choose us—for consistent quality, on-time service, and real value that supports their success.

2000+ Brake Shoe Models Cover All Your Need

We’ve developed over 2,000 brake shoe models, covering a wide range of vehicles—from passenger cars to trucks and commercial vehicles. So there’s a good chance we already have what you need. If not, just send us your sample—we can develop a custom mold to meet your requirements. With our extensive catalog, we’re able to match the right models quickly and provide you with a fast, accurate quote.

Strong Production Capacity to Support Your Business

Our brake shoe production facility spans over 20,000 square meters and includes more than 110 skilled workers. With advanced equipment and an experienced team, we’re able to maintain smooth production, steady delivery times, and reliable product quality. Whether you’re placing a small order or a bulk purchase, our strong manufacturing capacity is ready to support your business with confidence.

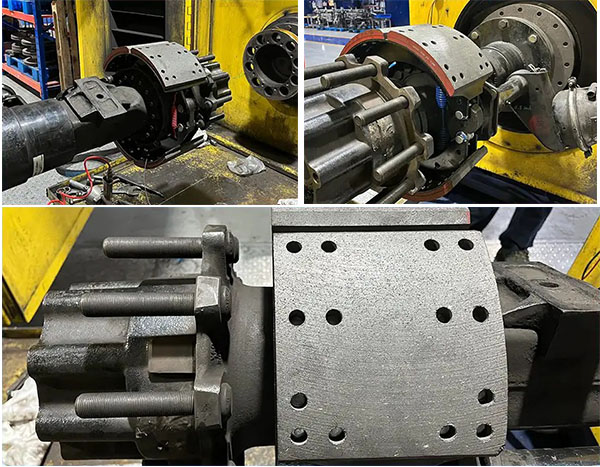

Advanced Quality Test Equipments

Quality isn’t just a claim—it’s built into every step of the process. Each brake shoe is tested using specialized equipment to ensure safe, consistent performance. This includes shear strength testing machines to verify bond integrity, hardness testers to check lining durability, and compressibility testers to assess pedal feel. We also use friction performance dynos to simulate real braking scenarios, measuring wear rate, noise, and fade resistance under high temperatures. By replicating extreme road conditions in our lab, we ensure every brake shoe is ready for the real world. With precise tools and a team that cares, these are brake shoes you can trust—and your customers will rely on.

Production Process of Brake Shoes

Step1: Material preparation

The materials used for making brake shoes, such as metal for the shoe base, and friction materials like organic, semi-metallic, or ceramic, are prepared. This may involve cutting, shaping, or forming the materials to the required dimensions.

Step2: Friction material application

The friction material, which is the lining that provides the braking action, is applied to the metal brake shoe base. This can be done through various methods, such as bonding, riveting, or molding. For organic brake shoes, the friction material is typically bonded or glued to the brake shoe base. For semi-metallic and ceramic brake shoes, metal fibers or particles are usually mixed with the friction material and then applied to the base.

Step3: Curing

If the friction material used requires curing, the brake shoes are then heated in an oven or pressurized mold to set or cure the friction material, ensuring it adheres securely to the brake shoe base.

Step4: Finishing

After curing, the brake shoes are refined through processes such as trimming and grinding to meet exact shape and surface specifications.

Assembly: Once the friction material is securely attached to the brake shoe base and the finishing processes are complete, the brake shoes may be assembled with other components, such as springs, pins, and clips, as required for the specific brake system.

Step5: Quality control

Throughout the production process, quality control measures are taken to ensure that the brake shoes meet the required standards and specifications, including visual inspection, dimensional measurements, performance testing, and other quality checks to ensure the brake shoes are safe and reliable for use.

Step6: Packaging

Finally, the completed brake shoes are packaged and prepared for shipping or distribution to customers or to be used in the assembly of complete brake systems.

FAQ About GDST

Are you a trading or factory?

We are a professional brake shoe manufacturer based in China, but also do foreign trading. As our customers grew confident in our quality and service, many began asking us to help them purchase other auto parts as well.

With their continued support, we’ve gradually expanded our offerings to include not only brake components, but also suspension parts, engine parts, and more. By working closely with trusted partner factories, we’re able to provide a reliable one-stop solution for your automotive needs.

Feel free to reach out with your inquiries — we’re here to help!

What’s your MOQ?

Normally, our MOQ is 100 sets per brake shoe model, but for new customers, we can offer just 50 sets to start. We’re confident in our quality and want to make it easy for you to try us out.

Can I Do My Brand Package?

Absolutely! We can customize your brand package —just send us your trademark certificate and authorization letter, and we also can print your logo or part number on the brake shoes.

What's Your Quality Guarantee?

GDST brake shoes are covered by a 12-month warranty. But our service doesn’t stop there—we’re here for you anytime with ongoing support, no matter how long you’ve been working with us.

How About Your Delivery Time?

It usually takes about 45 days to deliver our brake shoes after confirming the order. But if you’re on a tight deadline, we’re happy to speed things up—just let us know what you need, and we’ll make it work.

Could I Get A Sample?

We’d love for you to try our brake shoes! Just cover the sample shipping cost, and we’ll refund it when you place your first order.

Customers Feeback

Our brake shoes are trusted by customers in over 100 countries, including regions like the Americas, Europe, Asia, and Africa. We’re proud to receive great feedback on our quality.

Let GDST Boost Your Business Today!

As a professional brake shoe manufacturer, we’re ready to respond quickly to your inquiries. To help us provide an accurate quotation, please feel free to leave a message with your inquiry list and the quantity you need. Our GDST team will get back to you within 6 hours with detailed pricing and any additional information you may require.