Currently, both iron and aluminum are the most common materials for brake cylinders and clutch cylinders on the market, and there are also plastics. However, plastic products are easy to wear and have a short service life.

The surface treatment methods used for products of different materials are different. For iron products, our main surface treatment method is electrophoresis. For aluminum products, we can do surface heat treatment according to customer needs, such as Sand Blasting, Original Oxidation, Hard Oxidation, and Dacromet.

The surface treatment of all products is actually to increase the internal and external hardness, thereby extending the service life of the products. However, each heat treatment method has its own advantages, and the price is naturally different. Customers can choose according to their needs. The following is our general introduction to the products after different heat treatments, hoping to help you understand these heat treatments and distinguish them.

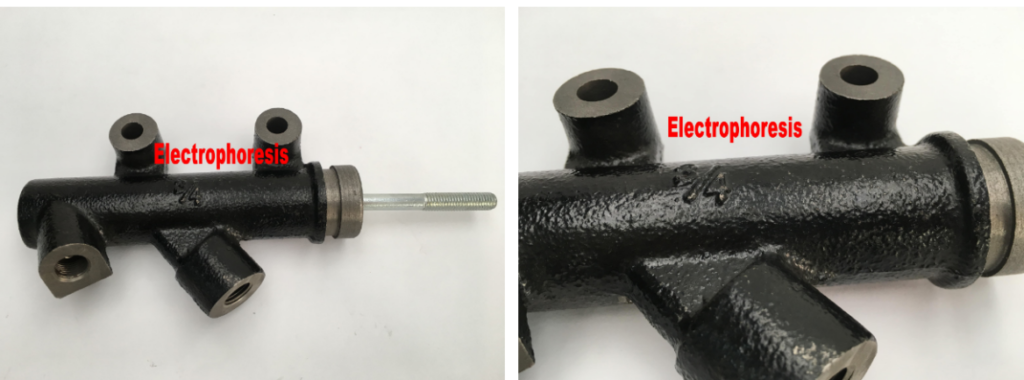

Electrophoresis

Electrophoresis is an electrochemical process used to apply a coating onto the surface of a cylinder. The cylinder is immersed in a bath containing a paint or coating solution, and an electric current is applied. The coating particles migrate and deposit onto the surface of the cylinder, forming a thin and uniform layer. Electrophoresis provides excellent corrosion resistance and can also offer a decorative finish.

The main advantages of Electrophoresis: It can prevent iron rust, discoloration, and corrosion.

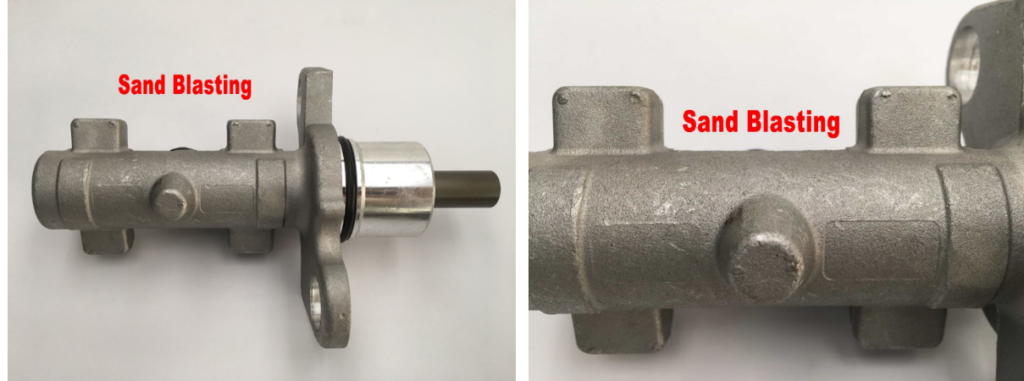

Sand Blasting

Sandblasting, also known as abrasive blasting, involves propelling fine abrasive particles at high velocity onto the surface of the cylinder. This process helps remove rust, old paint, dirt, and other contaminants from the surface, creating a clean and roughened surface. Sandblasting is often used as a preparation method before applying other surface treatments like plating or painting.

The main advantages of Sand Blasting: It can improve the fatigue resistance of the product, extend the durability of the coating film, and is also conducive to the leveling and decoration of the coating.

Original Oxidation

Original oxidation refers to the natural oxidation process that occurs on the surface of certain metals, such as aluminum. Aluminum cylinders, when exposed to air, develop a thin layer of oxide called aluminum oxide. This oxide layer provides some corrosion resistance and can be further enhanced through anodizing.

The main advantage of Original Oxidation: The surface of the product after the original oxidation is very close to the OEM one.

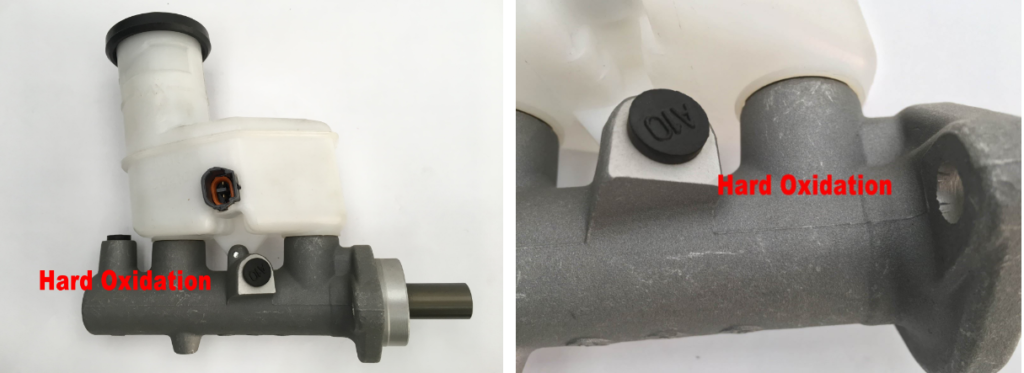

Hard oxidation

Hard oxidation is an advanced form of anodizing primarily used for aluminum cylinders. It involves subjecting the cylinder to a more rigorous anodizing process, resulting in a thicker and harder oxide layer. Hard oxidation improves wear resistance, hardness, and corrosion resistance of the cylinder surface, making it suitable for demanding applications.

The main advantages of Hard Oxidation: It can increase the surface hardness of the product. It has high wear resistance, strong adhesion, good insulation, and is non-toxic. (The oxidation time determines whether the surface color of the product is dark or light. The longer the oxidation time, the darker the surface color.)

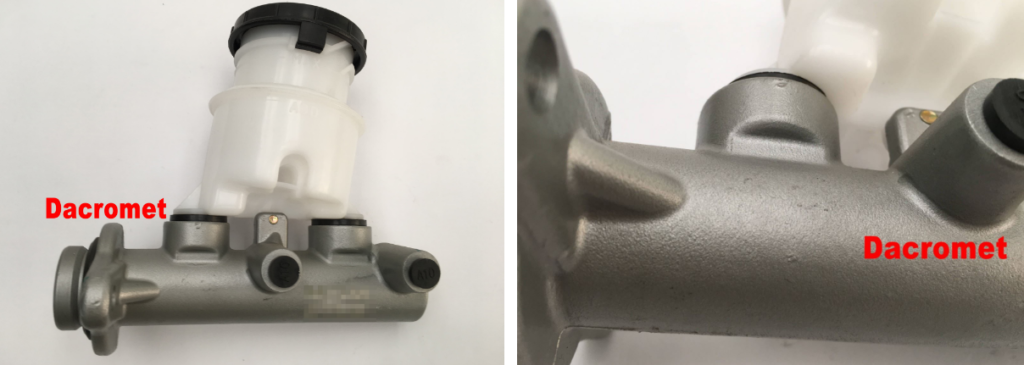

Dacromet

Dacromet is a specific type of coating commonly used for fasteners and other metal components, including brake and clutch cylinders. It is a thin, metallic zinc-based coating that provides excellent corrosion resistance and offers a self-lubricating effect. Dacromet coatings are highly durable and can withstand high temperatures and harsh environmental conditions.

The main advantages of Dacromet: It has strong corrosion resistance, high heat resistance, good recoating performance, and the surface looks smoother.

In conclusion, GDST is a leading manufacturer of brake cylinders, offering a range of high-quality and reliable brake cylinders and clutch cylinders. Our brake pumps are meticulously designed and manufactured using advanced techniques to ensure optimal performance and durability.

By choosing GDST, you can have confidence in the quality and reliability of our brake pumps. We are committed to delivering exceptional products and providing superior customer service and support. Whether you have inquiries or require further information, our dedicated team is ready to assist you.